O.A. NEWTON

ABOUT O.A. NEWTON

O.A. Newton has over 100 years experience in bulk material handling systems to the wood-plastic composite, flexible and rigid PVC and Carbon Black markets.

The company engineers, fabricates, and installs complete systems for the unloading, storage, conveying, and blending of process ingredients, including controls and ancillary equipment.

O.A. Newton has been a single-source provider of turnkey material handling systems for customers throughout the world. The company serves the plastics, tire, and other industries, including those processing dry bulk solids and hard-to-handle materials. In plastics, it has extensive experience in providing systems for processors of rigid and flexible PVC and wood-plastic composites.

Our 100+ year history has a rich background because of the strong entrepreneurial spirit of our founders. That entrepreneurial drive is still in place with the current management and ownership, which is fourth generation. We have a history of investing heavily in the business to keep it relevant for future generations and our success is only possible because of our knowledgeable, experienced and caring employees who make up our company.

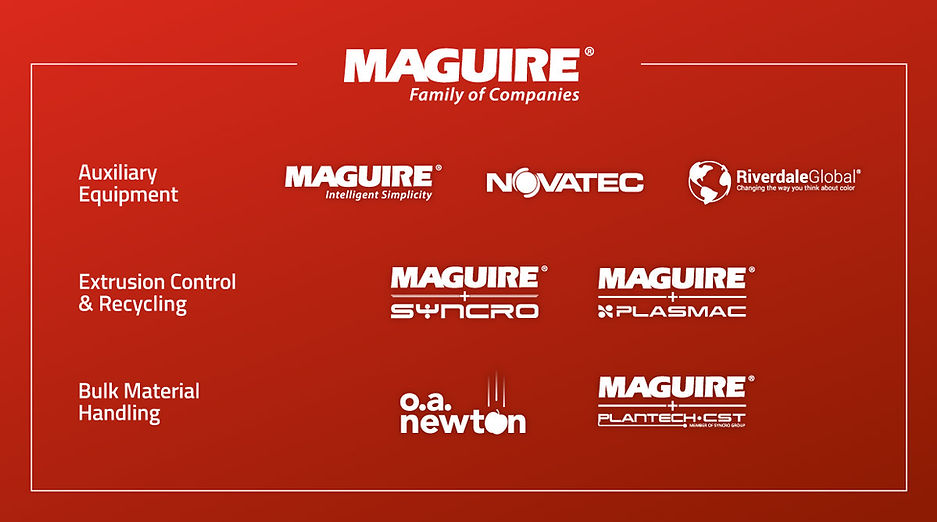

MAGUIRE FAMILY OF COMPANIES

Steve Maguire founded Maguire Products in 1977. He has since established ownership positions in other plastics businesses including O.A. Newton, and holds an ownership position in Novatec, which, like Maguire Products, is a supplier of auxiliary equipment for molding and extrusion.

"The investment in O.A. Newton broadens our offering to the plastics industry and allows us to serve markets that we would otherwise never reach with our current product line," said Mr. Maguire. "We can now refer inquiries for bulk material handling directly to O.A. Newton and can work together with them as projects require.”

“Our affiliation with the Maguire family of companies provides us with access to a sales organization that has a global reach," said Rob Rider, CEO and part owner of O.A. Newton. "This relationship will greatly improve our ability to grow our customer base. The synergies between all the companies will have a compounding effect on all of us.”

Steve Maguire also holds an ownership position in the Syncro Group, which offers extrusion upgrades, inline and offline recycling, and bulk powder material handling.

The Early Days

OUR HISTORY

O. A. Newton and Son Company, founded in 1916, began as a feed and chick business. After having difficulties in securing parts and service for the feed business, we began to serve the local area as well as ourselves. We then progressed to the point where we built our own feed mill and in the early 1950’s. We began to build complete feed mills and grain handling facilities for others.

Today, the company is no longer in the poultry business, but we remain close to our roots in agriculture and material handling.

A Global Material Handling Business

TODAY

Our history in feed and grain handling has evolved into a global Material Handling Business.

O. A. Newton is in the business of engineering, fabricating, and installing Engineered Material Handling Systems. We operate primarily in the profile extrusion arena, handling PVC powders, wood flour, and other powdered ingredients that make up an extruded profile in the building products industry.

Remaining Close to Our Roots

OUR EXPERTISE

Our areas of expertise include Railcar Unloading, Storage Silos, Pneumatic and Mechanical Conveying, Mixing and Blending (including Weighing Systems), Pelletizing and Drying, Extrusion Feed Systems, and complete plant engineering including Control Systems.

We have completed projects all throughout North America and Mexico. Additionally projects have been installed in France, Greece, Czech Republic, Japan, China, Columbia, and Brazil.

Innovating the Industry

OUR PATENTS

The Micro Ingredient Controller, on which we hold patents, is one of our innovations and has received universal acceptance throughout the industry.

Additionally, we have a patented Heated Screw Conveyor which is mainstay in the Carbon Black Handling Industry through our brand, TKC Technologies.

TEST LAB AND PILOT PLANT

Testing and Development

O. A. Newton is currently adding a turnkey test lab and pilot plant for Pelletizing and Extrusion.

This will enable us to both do testing and development with our equipment, while also running product trials for our customers.

We receive many inquiries from customers that are in the development phase in the area of wood plastic composites or WPC. They are often looking for a way to run trials on a new product - either because they do not want to interrupt current production, or they do not have any production at all yet.

Because we deliver turnkey solutions to our customers, to be able to add product development capabilities to our business would greatly enhance our relationship with our customers and put us even more in the strategic partner category with them. All the while we are doing this, the lab gives us the capability to run tests on new or improved equipment that we build.

This lab will be located in our 165,000 SF manufacturing facility. Laboratory equipment:

-

Labaratory sieve analysis equipment

-

Laboratory oven

-

Equipment to determine plastic properties, melt flow index

-

Instron tensile strength tester.